Mastering Complex Pattern Roll Goods: A Ballroom Installation Use Case

- 20 Aug, 2025

- Use Case Library

Project Details

Measure Square Solution:

When working with patterned roll goods, careful planning is essential to avoid shortages, mismatches, or costly delays. Measure Square helps you visualize and calculate pattern carpet needs before the job ever starts.

This project showcased several of the powerful pattern roll goods capabilities:

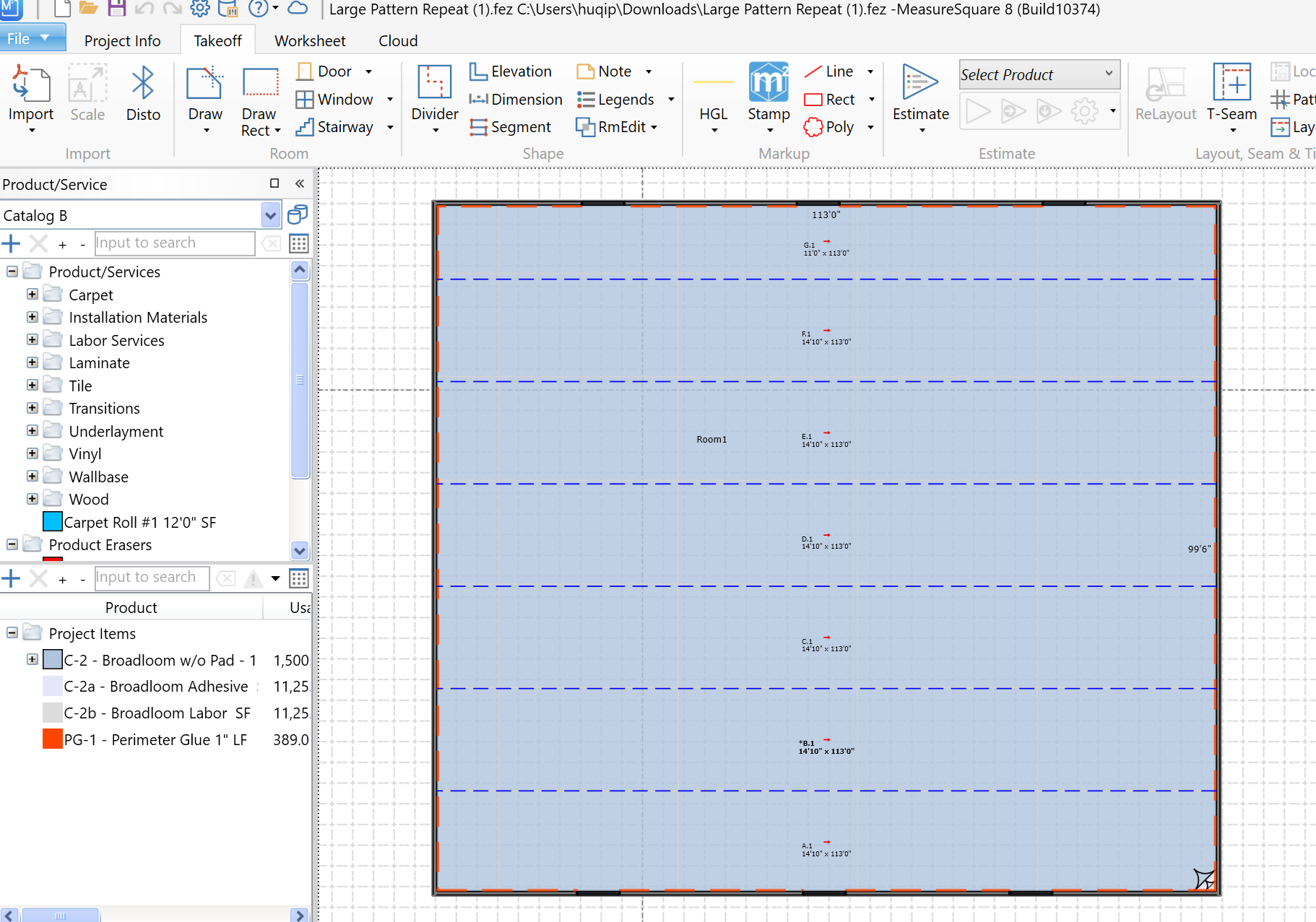

Pattern Repeat Configuration

MeasureSquare 8 automatically recognized the full-width pattern repeat, understanding that each roll width represents one complete pattern cycle. This intelligence is crucial for accurate material calculations and waste minimization.

Intelligent Margin Settings

The system applied strategic margins where they matter most:

- Width Margin: 2" - 6" depending on the amount of freight damage

- Length Margin: Cut margin on length only, since full-width shots are used

- Linear Length Roundup: 1' buffer to allow for warpage on the pattern visual

Seam Optimization

MeasureSquare 8 positioned seams to start with a full run from the doorway, bleeding off toward the back of the room. This approach ensures the most visible area presents perfectly aligned patterns while managing transitions in less prominent zones.

Technical highlights:

Video Tutorial:

Key Takeaways:

- Accurate Quantities: The system provided solid material calculations despite visual rendering quirks

- Installation-Ready Planning: Field-cut configuration and proper margins set installers up for success

- Professional Presentation: Visual tools help customers understand the finished result

- Waste Optimization: Intelligent seam placement and pattern management minimize material waste

Remember: Measure Square is a powerful tool, but it requires knowledgeable operators who understand both the software's capabilities and real-world installation requirements. Master both, and complex pattern projects become profitable opportunities rather than risky ventures.

Interested in trying out patterned roll goods in MeasureSquare 8? Download your free 14-day trial: click here.