Effectiveness Over Efficiency: Paul Menninger’s Approach to Stone Fabrication Using MeasureSquare Stone & Tile

- 06 Oct, 2025

- Customer Stories, Stone & Tile, Stone Takeoff Estimating

How A Stone Fabricator Uses MeasureSquare Stone & Tile to Prevent Rework, Handle Change Orders, and Align Teams Using Tagging

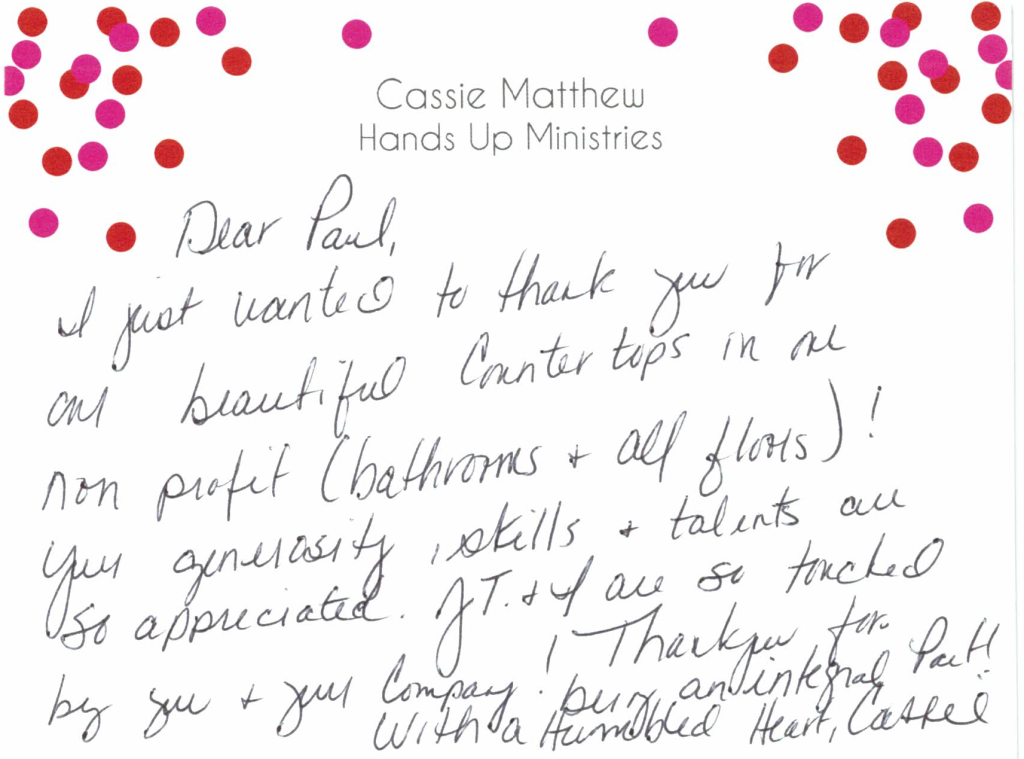

According to Paul Menninger, most business owners in the stone and countertop industry focus on net results: margins, jobs completed, revenue. What often gets overlooked is accuracy at the front end. With MeasureSquare Stone & Tile stone fabricator software, Paul and his team at Capitol Granite don’t just maintain accuracy; they prevent costly errors before they ever happen.

Previously, Paul relied on Bluebeam, where nearly 50% of his time was spent figuring out where the deviations were between the initial takeoff and what was actually installed. Today, that same time goes into estimating and winning jobs–a transformative shift.

Being able to implement tagging, affiliating parts, and phased work have made his workflow smoother, more transparent, and more resilient when it comes to handling inevitable change orders.

And Paul knows a thing or two about innovation. Early in his career, he worked with Flow International to program waterjet machines, back when jobs had to be programmed from hard templates. It was redundant, error-prone work, and it showed him firsthand the cost of inefficiency.

Around that time, he founded Capitol Granite. A decade later, the company expanded into the commercial sector, where Paul quickly encountered a major challenge: over- or under-ordering materials.

“We made our way into the commercial sector where the margins are better, but the risk is also higher. The downside is greater if you do it wrong. The upside is very lucrative if you’re capable of doing it right.”

Key milestones since then include going fully digital about eight years ago, expanding into a 24K square foot facility, and, most recently, adopting MeasureSquare Stone & Tile in 2023–all of which paved the way for smarter, more efficient workflows.

Consistent Nomenclature via Tagging: Staying Aligned

For Paul, tagging inside MeasureSquare Stone & Tile stone fabricator software has been a game changer. “All the activities associated with a project are seamlessly connected. We can phase the work, affiliate the parts, and keep every file consistent throughout the process,” he explained.

That consistency is especially powerful once jobs hit the shop. By tagging sinks, splashes, cutouts, and edges during the takeoff, those details flow directly into fabrication drawings with no risk of getting lost in translation. Instead of relying on notes or renaming parts by hand, Paul’s team delivers complete files to the shop, making it clear what gets cut, fabricated, and installed.

The result: smoother handoffs, fewer mistakes on the floor, and far less rework.

“The opportunity cost of preventing rework is massive. Rework isn’t just material; it’s labor, managing the shop, interrupting everyone’s life. Measure Square cuts that out upfront,” Paul explained.

Phased Work: Managing Complex Jobs Without Overbuying

Commercial projects often require work to be broken into phases–bathrooms first, then a salad bar, then the rest of the space. Without planning, material orders quickly go wrong. MeasureSquare Stone & Tile lets Paul label phases within the same file and run slab optimization accordingly.

“There’s nothing worse than buying 12 slabs for a 12-slab job, only to find out later you need 14 because the work was phased,” Paul said. “Measure Square makes sure that doesn’t happen.”

Unified Teamwork & Handling Change Orders

Measure Square Stone & Tile doesn’t just improve accuracy; it keeps the entire team aligned. From sales to fabrication to installation, everyone works from the same tagged parts, phased plans, and takeoffs.

Change orders, while unavoidable, no longer derail projects. Paul can model scenarios in advance, compare slab sizes, tie labor estimates to material choices, and instantly see the cost and yield impact of each option. In conversations with owners or designers, he can adjust the takeoff and provide a visual, accurate answer without starting over.

“Being able to do it fast and right is key to this game,” Paul said. “That speed and accuracy set us apart. In the past, change orders meant manually adjusting drawings and losing hours to rework. With Measure Square, that’s gone.

Value Engineering: Winning Jobs With Smarter Proposals

MeasureSquare Stone & Tile has also given Paul a competitive edge in bidding. Instead of submitting a single number, he can test alternatives on the fly, swap slab sizes, and generate new layouts without redoing entire takeoffs. This allows him to present clients with options, explain cost impacts with visuals, and educate them on choices competitors rarely highlight.

“With Measure Square, I can lay out a project, calculate the slabs needed, then create another version by adjusting seam locations to get a much better material yield,” Paul explained. “That lets me pass most of the savings on to the client in a true value-engineered proposal.”

The software also makes it easy to adapt layouts across different slab sizes, thicknesses, or layers.

“I can convert, add, and reprice with just a few clicks,” Paul said. “That lets me quickly present multiple options, show the value proposition, and position us as a partner rather than just a contractor.”

“Our competitor gives a number. We give a number with proof,” Paul added. “That transparency puts us in a different light with the same set of clients.”

This ability to value-engineer has translated into winning more jobs–and often, repeat business.

From Damage Control to Estimating

The personal impact for Paul has been dramatic. “I used to spend 50% of my time fixing problems from an inefficient process. Now, I spend that time estimating,” he explained. “Production installs the job, and I don’t hear about it again until it’s time to invoice.”

That shift, from damage control to proactive estimating, Paul says is difficult to quantify but invaluable for both efficiency and peace of mind.

From Bluebeam to Measure Square: A Necessary Leap

Paul’s experience with Bluebeam underscored the gaps that MeasureSquare Stone & Tile filled. In Bluebeam, there was:

- No consistent nomenclature: Different names for the same part at each stage

- No ability to affiliate parts: Notes were the only workaround

- No phased work: Making complex jobs risky to bid

- No visual representation: Harder to scope jobs or catch errors

With MeasureSquare Stone & Tile, Paul gained the optics, accuracy, and flexibility that Bluebeam couldn’t provide.

Stone-Specific Tools: Built for Fabricators

In addition, what really caught Paul’s eye when first getting a demo of MeasureSquare Stone & Tile, were the stone-focused tools built directly into the software.

“When I first saw it with Matt at a trade show, I was blown away by how fast and visual takeoffs were,” Paul said. “Affiliating splashes, laminations, and creating substrate layers was simple. Everything’s built for stone, and nothing extra gets in the way.”

With MeasureSquare Stone & Tile, he can:

- Visually create shapes

- Add miters or backsplashes with a single click

- Tag every detail for accurate tracking

- Segregate and categorize parts for fabrication

Through the Slab Optimizer in MeasureSquare Stone & Tile, Paul can:

- Nest pieces in a project

- Test different slab sizes

- Calculate material yield

For Paul, that clarity is crucial: “Stone is our biggest cost center. If I can get the yield right, I know what the job is really going to cost.”

The result is an accurate takeoff that ties directly into fabrication, helping Paul focus on doing each job right the first time.

Effectiveness Over Efficiency: Paul’s Philosophy

Paul believes Measure Square’s biggest strength is that it supports his philosophy of effectiveness over efficiency. While most of the industry focuses on pushing more square footage through the shop, Paul zeroes in on doing it right the first time.

“Nobody talks about effectiveness, or doing it right the first time, on time, every time. Efficiency doesn’t matter if you’re doing the same thing twice and not getting paid for it,” he said.

For him, effectiveness means fewer errors, less rework, and more profit. “If you focus on effectiveness, all the efficiency metrics fall into place anyway,” Paul explained. “You make more money by doing it right upfront.”

Final Thoughts

With MeasureSquare Stone & Tile, Paul has turned effectiveness and preventative processes into a competitive advantage, proving that doing it right the first time is the best path to profit, repeat business, and client trust.

For more information on MeasureSquare Stone & Tile, click here.

To schedule a free demo, click here.